YOU HAVE NO ITEMS IN YOUR CART.

Featured Manufacturers

Columbia Safety and Supply Safety Stand-Down Week 2022: Objects are Falling

Day Five

Falling Objects Prevention

Dropped Objects Kill

Dropped objects are the third largest cause of workplace fatalities around the world. In a single calendar year there were over 50,000 reported incidents of dropped or falling objects from a higher level to the ground or a lower level on construction sites. These objects could be tools, structural equipment, safety gear like hard hats, or other objects. This number is also likely low as many unreported incidents probably occurred which were not documented. Worst of all, these events caused over 230 fatalities.

In 2018 ANSI 121-2018 was adopted. This is a voluntary consensus standard establishing minimum design, performance, and labeling requirements for product solutions and guidelines for testing. OSHA requires employers to address falling/dropped objects on the job in both general industry (1910.23 & 1910.28) and construction (1926.451, 1926.501, 1926.759) standards. This means that OSHA does require that falling object risks be addressed.

What is Tool Tethering?

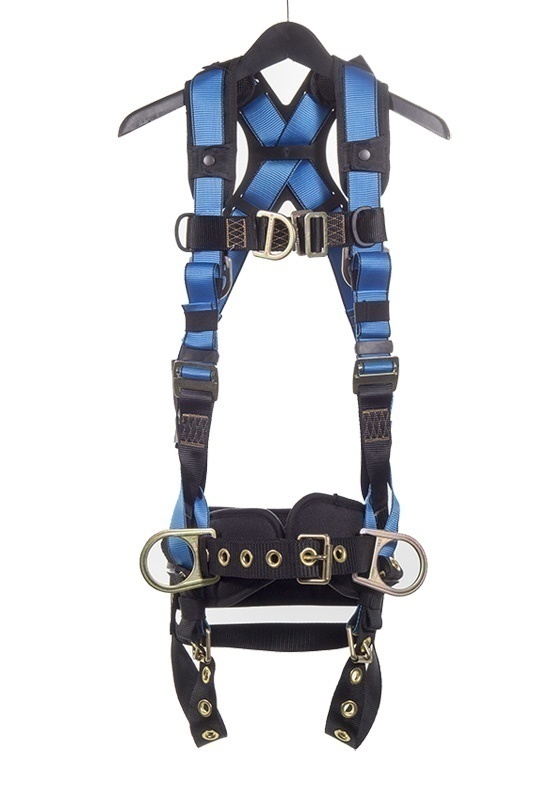

At the basic level, tool tethering is exactly what it sounds like. It’s the method of attaching a tool that you’re using to either yourself, a harness or bag, or the structure you’re working on. But there’s more that goes into it than simply wrapping some duct tape and cord around a wrench. Weight limits, forces applied during a dropped object event, and many other factors go into a proper tool tethering program.

What are some things to think about when establishing a tool tethering program?

Q: What type of tool are you tethering?

A: This will help identify the proper method & products needed to secure your tools

Q: How much does your tool weigh?

A: The majority of certified fall prevention products made for tools are rated based on the weight they will hold. Knowing the weight of your tool will ensure you apply the appropriate weight rated attachment points,

tethers, and tool anchors.

Q: Does the tool have any pre-drilled attachment points that are rated to be tethered?

A: If yes, it’s possible to tether directly to the tool OR add an attachment point for ease of switching out tools on the job. If not, a weight rated attachment point will need to be added to the tool. This will

provide you with a tether point to attach a lanyard.

Q: Is it a specialty tool that will require a tool trap?

A: Tool specific tool traps are made for installing attachment points on tools like tape measures and power tools, where applying a standard attachment point does not work or would impede the tools primary function.

What makes standardization so crucial, and how can you make the most of the process?

Ensure that your tool lanyards meet the minimum standards for safety!

Lack of standardization makes it more difficult for teams to communicate. Using different devices across a jobsite not only can confuse workers who move from one area to another, but could leave them unprepared with their normal dropped object prevention gear. Large amounts of variation within and through the company should be avoided.

The benefits of uniformity throughout your company and jobsite included, but are not limited to increased productivity of your workforce, reduction in tethering errors, improvement in expectations of safety, and opportunities for continuous improvement.

Questions or Need More Info?

If you have any questions regarding the above information or need more insight into safety or fall protection in general, reach out to our Gear Experts®! Click here to contact our team, or use the instant chat feature in the lower right hand corner of your browser screen. Also be sure to connect with us on social media to keep up with all of our latest content.